VRS Terminal

The VRS Terminal was developed for diagnostics and control of automated industrial machines that can be operated with specialized terminal equipment in case of failures. Such terminal equipment is usually expensive, hard to replace, difficult to use and carry and completely incomparable to modern technology we carry in our pockets today

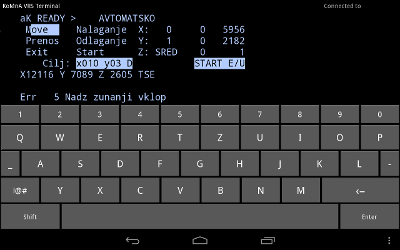

The VRS Terminal replaces currently used terminal equipment with two devices: a communication module that enables connectivity between the machine we want to control and a mobile phone or tablet computer with the VRS Terminal software.

The VRS Terminal is and Android application that translates messages and signals between an Android device and the industrial machine we want to diagnose or control.

Depending on the communication port (type and connector), a generic Bluetooth serial adapter can be used as the communication module to connect the industrial machine and the mobile device running VRS Terminal. If a generic Bluetooth adapter can not be used, the KoMnA communication module is used. The KoMnA communication module is developed for use in industrial conditions: it offers a wide range of options regarding connectors, power source, mounting and environment conditions.

The combination of an Android mobile device and Bluetooth communication was used to achieve a wide range of possibilities regarding the available hardware solutions on the market. An Android mobile device enables the use of mobile phones already used by the service crews. Considering that a failure rarely happens in an area that is easily accessible, that allows a lot of movement (hight or narrow corridors) or use of large, heavy and clumsy equipment, a mobile phone with Bluetooth connectivity can be considered a better option than a communication cable. Also, Bluetooth communication is standard for all Android devices with a Bluetooth module, while cable communication is not.

VRS Terminal software

System requirements for the VRS Terminal are Android 4.0 or higher, screen resolution of at least 800x480, Bluetooth 2.1. and 200MB of free space.

The characteristics of the VRS Terminal software are:

- runs on a wide range of Android devices,

- connectivity with any Bluetooth device compatible with the SPP standard,

- support for different communication profiles for different machines,

- emulation of a physical keyboard with an adjustable key repeat rate,

- custom keyboard layout and number of keys on the keyboard,

- adjustable keyboard and screen size,

- adjustable screen orientation (landscape or portrait),

- adjustable keyboard position (top/bottom),

- option to record all communication between the controlled machine and the mobile device on the device,

- recording extensive logs for diagnostic purposes.

Usage

The VRS Terminal is typically used in two ways:

On locations where we want to control multiple identical machines that have few failures and are easily accessible, a portable communication module is used. The module is in a small housing with a magnetic side and a short communication cable. The module is attached to the machine with the magnet and connected with the communication cable. The machine is then switched to manual operation. The maintenance crew connects to the machine with the mobile device trough the VRS Terminal.

On locations where the machines we want to control require frequent interactions or are not easily accessible, the communication module is fixed to the machine. The most optimal localtion and housing is used for the module, so that the movement of the machine is not obstructed in any way and the easiest and best connectivity with the mobile device is assured.

Since mobile screens can be small to use, the use of a 7" tablet computer is recommended. We recommend a rugged tablet computer or at least the use of a good screen protector and case (such as BobjGear).

KoMnA communication module

The communication module was developed for use in industrial conditions. The Bluetooth connectivity enables communication with an Android device and other Bluetooth enabled devices. A PC can be used for analysis and diagnostics of a problematic industrial machine from a safe distance, together with other diagnostic software.

The communication module is customizable and enables:

Warning

Verify all routes are free of obstacles before use. Verify you or anyone else is not in danger in case of sudden and unexpected moves of the controlled machine. When using the terminal equipment you must be standing on the location, designated for use of the terminal. Usage of the terminal equipment outside of designated locations is not recommended, since communication errors can occur that can cause sudden and unexpected moves of the controlled machine.

Users

Some major facilities that use VRS Terminal:

- Lek d.d., Prevalje (automated VNA warehouse for raw materials),

- Steklarna Hrastnik d.d., Hrastnik (automated VNA warehouse for finished and semi-finished goods).

VRS Terminal is aslo compatible with the automated lifts and trucks at the following locations:

- AERO Celje (automated VNA warehouse for paper rolls),

- Iskraemeco (automated VNA warehouse of finished goods and repro material),

- KRKA Novo mesto (automated VNA warehouse for packaging),

- Merkur (Lesnina) Ljubljana (automated VNA warehouse for furniture),

- LIV Postojna (automated VNA warehouse for finished and semi-finished goods).

and other systems based on GESPAC, BINAR and SIEMENS computer systems.

The VRS Terminal usually needs special customizations for individual machine. Contact us regarding your requirements.